The optimal quality process

It is essential to minimize scrap and rework to produce high-quality and cost-efficient goods. The first step towards an optimized first pass yield is a systematic collection of relevant quality data. Data collection should start during the production process and not only after the completion of the product.

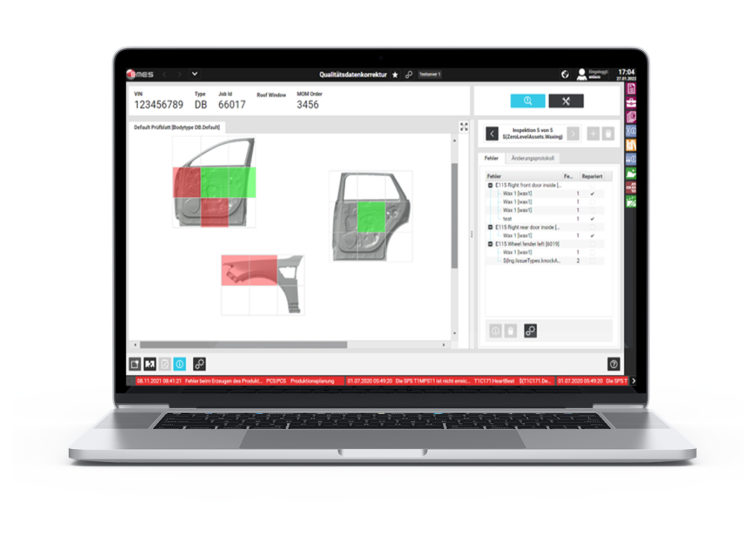

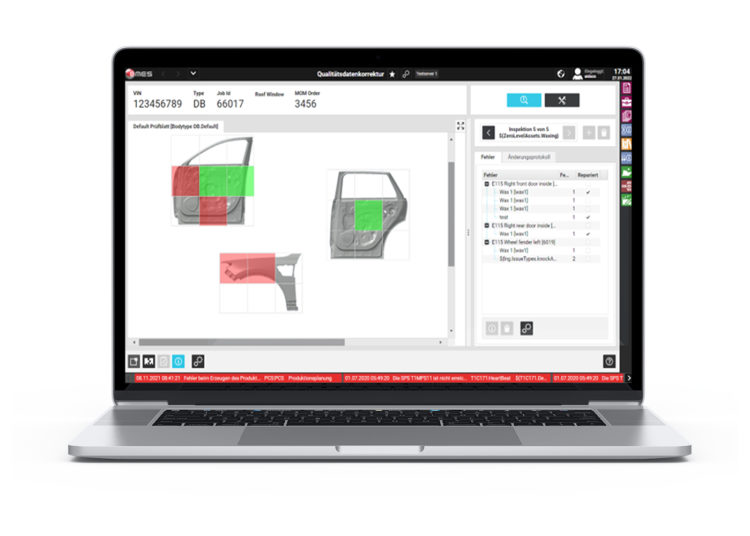

The “Product Quality Check” (PQC) application from ENISCO enables a quality and repair process that accompanies production and can be configured to customer specifications. This allows you to flexibly make the necessary adjustments at any time in the event of changes to the product or process. Previously recorded defect images and data are made available, thus simplifying and accelerating rework and repair processes.

Correspondingly, extensive evaluation options form the basis for your continuous improvement process (CIP).

Your added value:

- You can configure your quality processes yourself (no expensive software adaptations necessary)

- You have an adaptable and history-proof quality tool even in case of changes

- You ensure that relevant data is clearly recorded with customizable store floor dialogs

- You increase the efficiency of rework processes through visual preparation of defects and defect locations

- Graphical and tabular evaluation options with numerous filter options serve as a basis for improvement processes