Questions?

You want to know more about the topic? We will be happy to answer your open questions about our solutions. Our specialists will get in touch with you.

In control of the production process at any time and place: ENISCO’s modular Manufacturing Execution System (E-MES) connects the factory horizontally, the entire manufacturing process, and vertically across all process levels. It offers integrated data acquisition, analysis and display, and end-to-end transparent production and logistics processes and provides the basis for mastering critical industrial challenges.

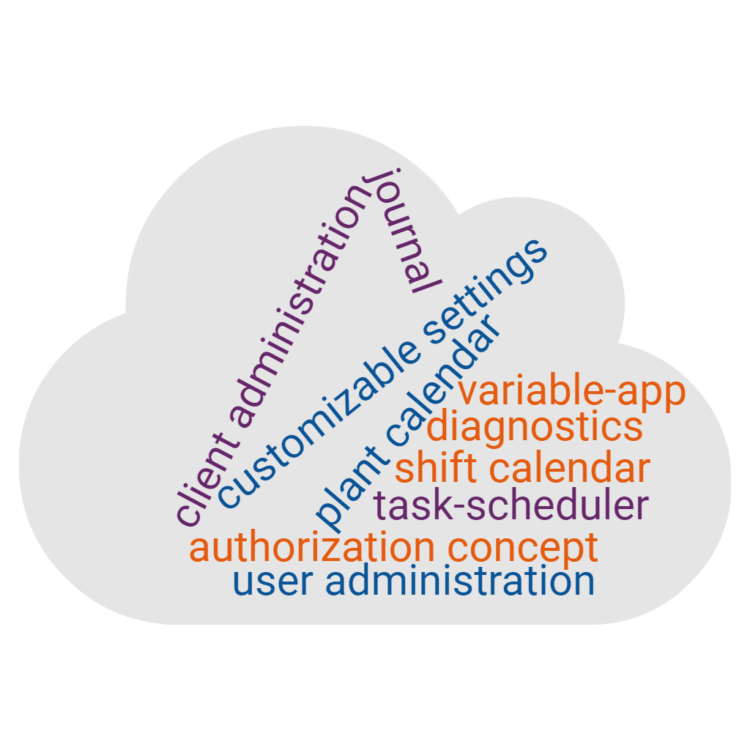

Our E-MES platform includes, on the one hand, the administrative area (see below) and, on the other hand, numerous apps that provide our customers with a high level of transparency. The following is a brief excerpt:

Our E-MES platform includes the administrative area and the basic MES functionalities. These include, e.g.:

Our E-MES is hardware-independent and works natively with all common controllers

E-MES integrates the proven industry standards (OPC-UA, MQTT, REST, etc.)

We thereby achieve very low latency in data communication

Our “Production Control System” (PCS) actively and highly flexibly controls the material flow through your production. By mouse click and drag & drop in real-time.

We will be happy to show you personally all the advantages of our MES

When was which workpiece in which process step? What production conditions prevailed at a specific time? Where do we stand with the number of units of the defined performance indicator?

E-MES provides all critical information through individually configured production statistics to reconstruct production processes and make the right decisions.

E-MES is based on a platform-independent modular principle. Customers can add additional function modules according to their needs. From simple operation and monitoring to planning and control functionalities, the E-MES portfolio offers customized solutions for every customer. The settings of the control system are always configured according to the specific requirements of the production.

E-MES is a browser-based, operating system-independent system. It enables users to access all data from anywhere in the world at any time, independent of a client installation. Higher-level control, monitoring, and production optimization becomes possible via tablet, smartphone or smartwatch. Employees on-site can manage the production and maintenance, as well as colleagues and managers from anywhere in the world.

You want to know more about the topic? We will be happy to answer your open questions about our solutions. Our specialists will get in touch with you.